Business Overview

At NF, we are dedicated to improving and transforming the environment with eco-friendly products.

Environmental Industry

Aqua Oxygen Supply System AOSS

Core Values of AOSS for Environmental Industries

AOSS is committed to using the power of oxygen to improve various industrial environments in an eco-friendly

way. By expanding the application of its multi-purpose oxygen supply system to areas like water quality

improvement and wastewater purification, AOSS aims to contribute to environmental sustainability.

- Versatility

- Carbon Neutrality

- Wide Range of Applications

Eco-Friendly Industrial Oxygen Supply System

AOSS promotes growth, activation, and purification in various environments by applying the diverse

benefits of oxygen. It maintains vitality in fish tanks, reducing mortality rates, and enhances crop growth,

increasing yields. When applied in livestock farms and purification facilities, it reduces odors and

purifies wastewater, expanding its role as an eco-friendly environmental improvement system.

-

- Oxygen Supply System for Aquaculture Facilities

-

- Oxygen Supply System for Industrial Facilities

An eco-friendly automatic oxygen supply system

for improving the environment

It is a system that can be used for various purposes, such as aquaculture and industrial facilities,

providing oxygen automatically in a safe, convenient, and eco-friendly manner.

- Increased Dissolved

Oxygen Levels

- Reduced

Mortality Rates

- Accelerated

Growth

-

Enhanced Water

Quality

-

Improved Feed

Efficiency

-

Increased Dissolved

Oxygen Levels -

Reduced

Mortality Rates -

Accelerated

Growth -

Improved Feed

Efficiency -

Enhanced Water

Quality

Safe and Convenient Automatic Oxygen Supply System

This system replaces traditional methods that relied on liquefied or gaseous oxygen to increase dissolved

oxygen (DO) levels. It eliminates the need for cumbersome cylinder refills and replacements, instead providing

a continuous supply of oxygen from an on-demand generation system, ensuring safety and convenience.

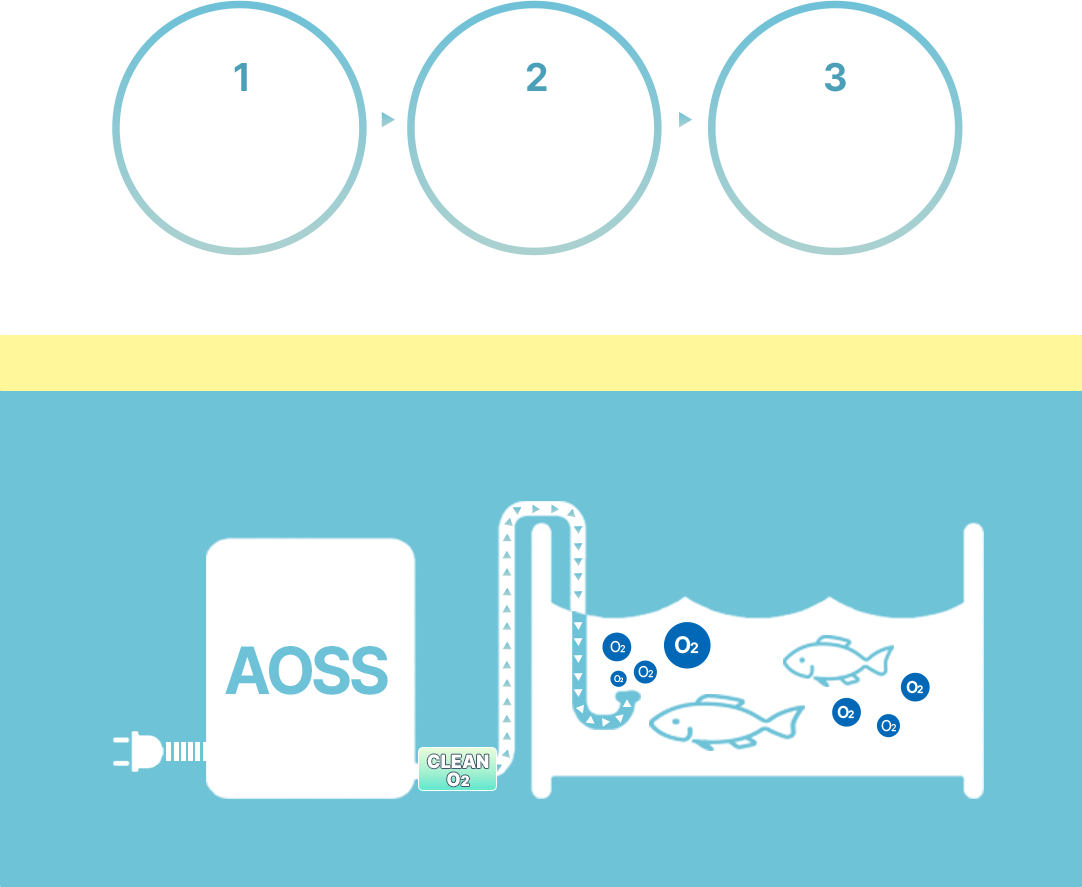

- Air Intake and

Nitrogen Separation - The oxygen generator

separates oxygen and

nitrogen from the air.

- Oxygen

Extraction - The separated oxygen is

filtered and delivered

through piping.

- Oxygen Supply to Fish

Farms or Aquariums - The oxygen is supplied to

fish through stones connected

to the piping system.

- Oxygen Supply Process

1 Air Intake and Nitrogen Separation

The oxygen generator separates oxygen and nitrogen from the air.

2 Oxygen Extraction

The separated oxygen is filtered and delivered through piping.

3 Oxygen Supply to Fish Farms or Aquariums

The oxygen is supplied to fish through stones connected to the piping system.

NF A/S Management System

-

Comprehensive business file management

Business information, product information, installation details

-

Regular inspection system

Every 3,000 hours for purity, flow, pressure, piping, and diffusers

-

Emergency response system

Holiday emergency team, liquid oxygen supply, emergency safety devices

-

Customer support system

Technical assistance, optimization of oxygen efficiency and piping

Key Advantages

-

Safe against oxygen supply interruptions

-

Convenient maintenance with no need for refills or exchanges

-

Easy operation and use

-

Significant cost savings compared to liquid oxygen

-

Reduced stress and mortality rates, improving overall quality

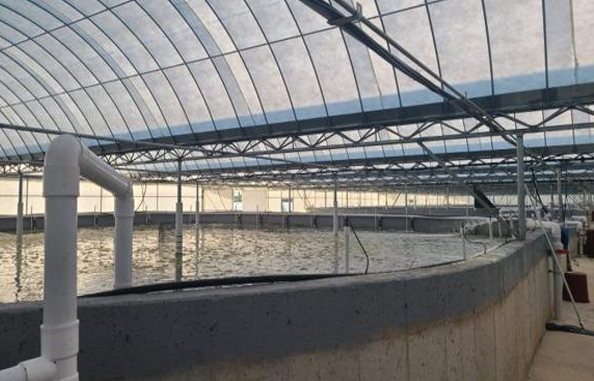

Application Examples

-

Smart Shrimp Aquaculture

Facility AD Fisheries -

Jirisan Sturgeon Farm in Yangsan

-

Exclusive contract

with Ulsan Jeongja Fish Market -

Dalwol Fishing Pond in Siheung,

Gyeonggi Province

NF oxygen generators are currently in use at over 400 locations across the Yeongnam region, including Busan Haeundae Aquarium, Goseong Paldaks Shrimp Farm, Changwon Navy Submarine Command, Indoor Fishing Cafés, Fish Hatcheries in Jeollanam-do, AD Fisheries Smart Shrimp Farm, Hatcheries and nurseries throughout the Yeongnam region, Sturgeon farms and storage tanks for live fish distribution, Jirisan Sturgeon Farms and Hatcheries, Trout Hatchery in Uljin Wangpiri , Kim Jin-kyu Soogari Farm in Sancheong, Wolsong Nuclear Power Plant’s Warm Water Aquaculture Facility

Comparison of Economic Efficiency with Liquid Oxygen

A cost-effectiveness comparison of producing the same amount of oxygen as

the AOSS oxygen generator in liquefied and vaporized forms

Oxygen Production * based on AOSS 450F

Daily 64,800L

Monthly 1,944,000L

For oxygen usage equivalent

to the oxygen generator’s output

Daily Consumption 0.5 cylinder

Monthly Consumption 15 cylinder

For oxygen usage equivalent

to the oxygen generator’s output

Daily Consumption 13 cylinder

Monthly Consumption 390 cylinder

Product Details

70u

70s

150F

200F

300F

450F

900F

| 70u | 70s | 150F | 200F | 300F | 450F | 900F | |

|---|---|---|---|---|---|---|---|

| Purity | 90±3% | 90±3% | 90±3% | 90±3% | 90±3% | 90±3% | 90±3% |

| Flow | 7 LPM ± 0.5 | 7 LPM ± 0.5 | 15 LPM ± 1 | 20 LPM ± 1.5 | 30 LPM ± 2 | 45 LPM ± 2 | 90 LPM ± 2 |

| Pressure | 1.5 ± 0.1 bar (Max 4.5) | ||||||

| Voltage | 220 VAC/60Hz | 220 VAC/60Hz | 220 VAC/60Hz | 220 VAC/60Hz | 220 VAC/60Hz | 220 VAC/60Hz | 220 VAC/60Hz |

| Power | 590w | 620w | 1.23 Kw/h | 1.90 Kw/h | 2.52 Kw/h | 3.74 Kw/h | 7.48 Kw/h |

| Weight | 23 Kg | 39 Kg | 69 Kg | 96 Kg | 123 Kg | 169 Kg | 338 Kg |

| Size | 230×562×517 | 560×410×663 | 530×646×853 | 765×646×853 | 1,000×646×853 | 765×646×1,560 | 1,540×646×1,560 |